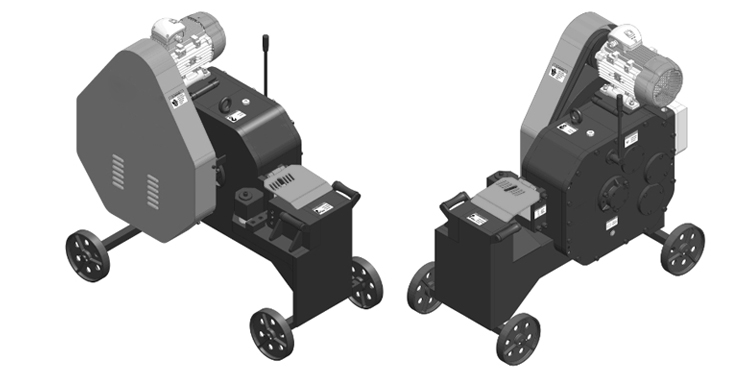

NB-52 Generation Series

- Ease of Operation

- Lower Oil Consumption

- Additional Safety for Motor

- Increased Life of Blades

- Longer Life of Machine

- Lower Frequency of Electrical Breakdown

- Lower Power Consumption

Our bar cutting machines are designed by adheres European safety standards.

Each part in this cutting machine is designed with advanced software with a goal to make the machine rugged, stronger & maintenance free.

Bar cutting machines are specially designed with the powder coated body parts for longer life and protection against rust.

This series is designed higher factory of safety for increase the life of machine up to 10 years.

Reducing speed and improving the life of blades vastly, we use double stage of helical gearbox design.

The cutting blades, made from special hardened steel, are designed to cut small and big diameter steel rods.

In this series machines, you can use four edges of cutting blades.

Minimum vibration and less noise while cutting bars. The machine is supplied with a dynamically balanced flywheel. This ensures the long life of the machine’s moving parts.

Purpose of saving money and making it very environmentally friendly, we design SpanTech series with significantly reduced oil consumption.

| Technical Specification | ||||||

| BAR CUTTING MACHINE SPECIFICATION | ||||||

| MODEL | Strock per min. | Ø Max. 60 Kg./mm2 | No. of Bars | Motor Kw (HP) | DimensionSize (mm) | Weight (Kg.) |

| SC 42 | 87 | Ø32 Ø20 Ø12 |

1 2 3 |

3.7 (5) | 540 x 1050 x 875(h) | 420 |