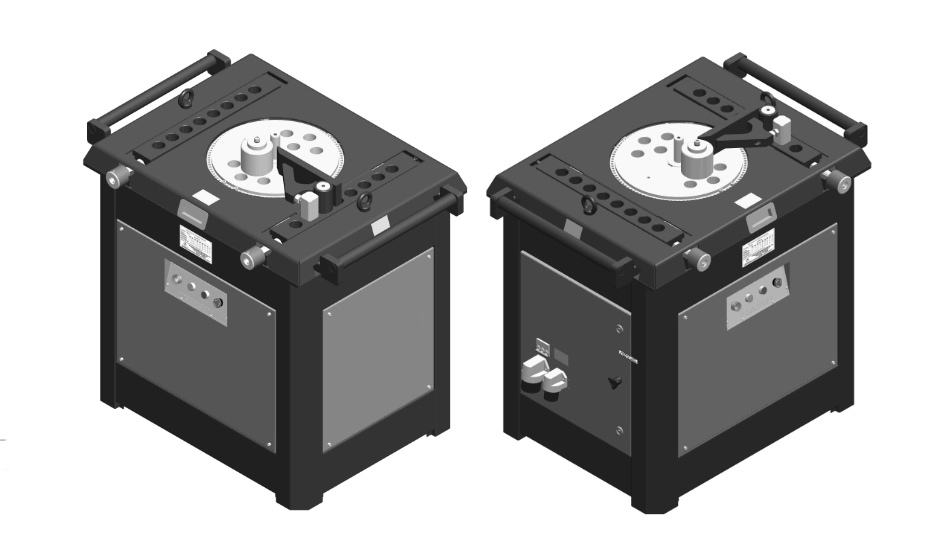

NB-55 Generation Series

Our bar bending machines are designed by adheres European safety standards.

The bending machine has all the Branded electrical components. It comes with delay timer and rectifier. With delay timer, the return operation is delayed for safety reasons.

In this series machine used of customized Italian planetary gearbox which coupled with the motor, eliminates the use of V-belt for reducing breakdown give higher torque and increases the productivity.

Expensive synthetic oil in these Italian gearboxes which eliminates the frequent changes of oil and increase the life of gear components.

Increasing the strength of the body to take a heavy load, finishing qualities & life by powder coating for better magnificent qualities. We manufactured sheet metal body of these machines on CNC punching and bending. We are using the advance CNC Laser cutting, CNC turning and VMC for manufacturing parts.

In SpanTech all the pins, bushes & rollers are supplied with electroplating for protection against rust & butter magnificent equality.

Specially designed electric braking logic circuit which safety stops the motor and which eliminates a need of brake motor thus, reducing break down and maintenance of changing brake liners.

We use Schneider make electrical contractors and Finder (Italian) make timers thus reducing the frequency of electrical breakdowns.

Imported heavy duty four switches with a top cover for protection from falling debris & material at sites.

| Technical Specification | |||||||||

| BAR BENDING MACHINE SPECIFICATION | |||||||||

| MODEL | rpm. | Ø Max. 60 Kg./mm2 | No. of Bars | Motor Kw (HP) | Bend Wheel Dia. (mm) | DimensionSize (mm) | Weight (Kg.) | Max. Bend Redius (mm) | Bushes Size (mm) |

| SB 55 | 6 | Ø40 Ø30 Ø22 |

1 2 3 |

5.5 (7.5) | 500 | 925 x 1210 x 1200 (h) | 545 | 6D of Ø36 5D of Ø40 |

Ø60, Ø70, Ø100, Ø120, Ø160, Ø220 |

| Optional | 8D of Ø40 | ||||||||